Introduction

In the realm of laser technology, CO2 lasers and fiber lasers are two of the most commonly used types. Both have unique characteristics that make them suitable for various applications, particularly in industrial settings such as cutting, engraving, and marking. Understanding the differences between these two types of lasers can help businesses make informed decisions about which technology best suits their needs. This article delves into the key differences between CO2 lasers and fiber lasers, covering aspects such as their working principles, advantages, disadvantages, and typical applications.

Working Principles

CO2 Lasers

CO2 lasers operate by exciting carbon dioxide gas within a sealed tube. When an electrical current is passed through the gas, it excites the CO2 molecules, causing them to emit photons. These photons are then amplified through a series of mirrors to produce a coherent beam of light. The wavelength of CO2 lasers typically falls within the infrared spectrum, around 10.6 micrometers, which is highly effective for cutting and engraving non-metallic materials like wood, acrylic, and glass.

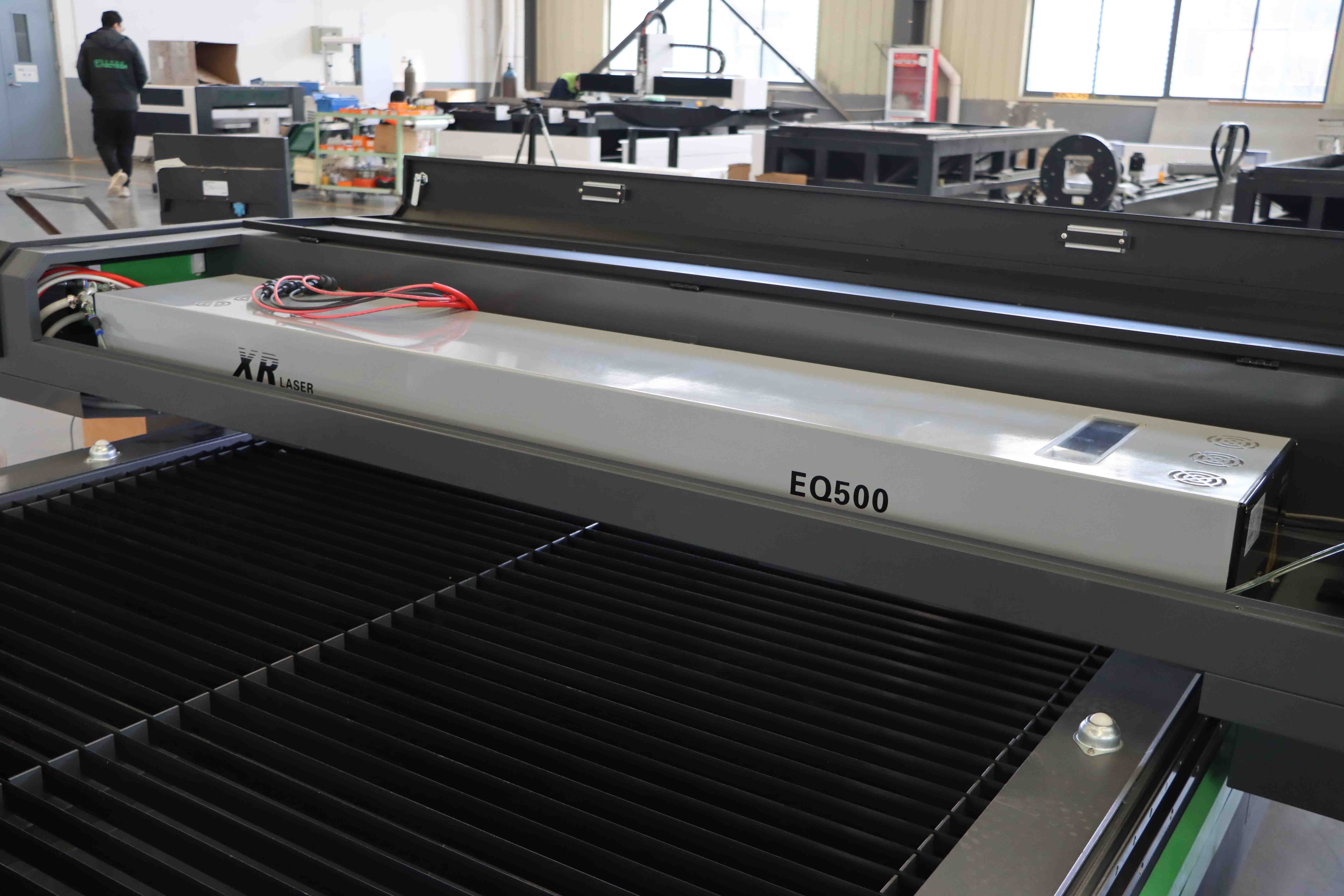

Fiber Lasers

Fiber lasers, on the other hand, use a solid-state laser source where the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, or neodymium. The laser light is generated within the fiber, which also serves as the waveguide, allowing for efficient and high-quality beam delivery. Fiber lasers typically operate at wavelengths around 1.06 micrometers, which is more suitable for cutting and marking metals.

Advantages and Disadvantages

CO2 Lasers

Advantages

1. Versatility CO2 lasers are highly versatile and can cut and engrave a wide range of materials, including non-metals and some metals.

2. High Power Output They can achieve high power outputs, making them suitable for thick material cutting.

3. Smooth Cutting Edges CO2 lasers produce smooth cutting edges, especially on non-metallic materials.

Disadvantages

1. Maintenance CO2 lasers require regular maintenance, including gas refills and mirror alignments.

2. Energy Efficiency They are less energy-efficient compared to fiber lasers, leading to higher operational costs.

3. Cutting Speed CO2 lasers are generally slower than fiber lasers when cutting metals.

Fiber Lasers

Advantages

1. Energy Efficiency Fiber lasers are highly energy-efficient, converting a higher percentage of electrical energy into laser light.

2. Low Maintenance They require minimal maintenance since they have no moving parts or gas to refill.

3. High Cutting Speed Fiber lasers offer faster cutting speeds, especially for thin metals.

4. Precision They provide high precision and excellent beam quality, making them ideal for fine engraving and marking.

Disadvantages

1. Material Limitations Fiber lasers are less effective on non-metallic materials compared to CO2 lasers.

2. Initial Cost The initial investment for fiber lasers can be higher, although this is often offset by lower operational costs.

Applications

CO2 Lasers

CO2 lasers are widely used in industries that require cutting and engraving of non-metallic materials. Common applications include

- Sign Making Cutting and engraving acrylic and wood for signs and displays.

- Textile Industry Cutting fabrics and engraving patterns on textiles.

- Packaging Cutting and engraving packaging materials like cardboard and plastic.

- Medical Devices Cutting and engraving medical devices made from non-metallic materials.

Fiber Lasers

Fiber lasers are predominantly used in metal processing industries. Typical applications include

- Automotive Industry Cutting and marking metal components for vehicles.

- Aerospace Cutting and engraving high-strength metal alloys used in aircraft.

- Electronics Marking and engraving metal parts in electronic devices.

- Jewelry Engraving and marking precious metals with high precision.

Conclusion

Both CO2 lasers and fiber lasers have their unique strengths and are suited for different applications. CO2 lasers excel in cutting and engraving non-metallic materials, offering versatility and smooth cutting edges. In contrast, fiber lasers are highly efficient and precise, making them ideal for metal processing applications. When choosing between the two, it's essential to consider the specific requirements of your application, including the types of materials you'll be working with, desired cutting speeds, and maintenance considerations. By understanding the differences between CO2 and fiber lasers, businesses can make informed decisions that optimize their operations and achieve the best possible results.

Regardless of whether you require general advice or specific support, we are happy to help you.