In the world of manufacturing and metalworking, precision and efficiency are paramount. Small laser metal cutting machines have emerged as a game-changer, offering unparalleled accuracy, speed, and versatility. These compact yet powerful machines are designed to handle a wide range of metal cutting tasks, making them indispensable tools for small workshops, hobbyists, and even large-scale industrial operations. This comprehensive guide delves into the intricacies of small laser metal cutting machines, exploring their features, benefits, applications, and key considerations for potential buyers.

What is a Small Laser Metal Cutting Machine?

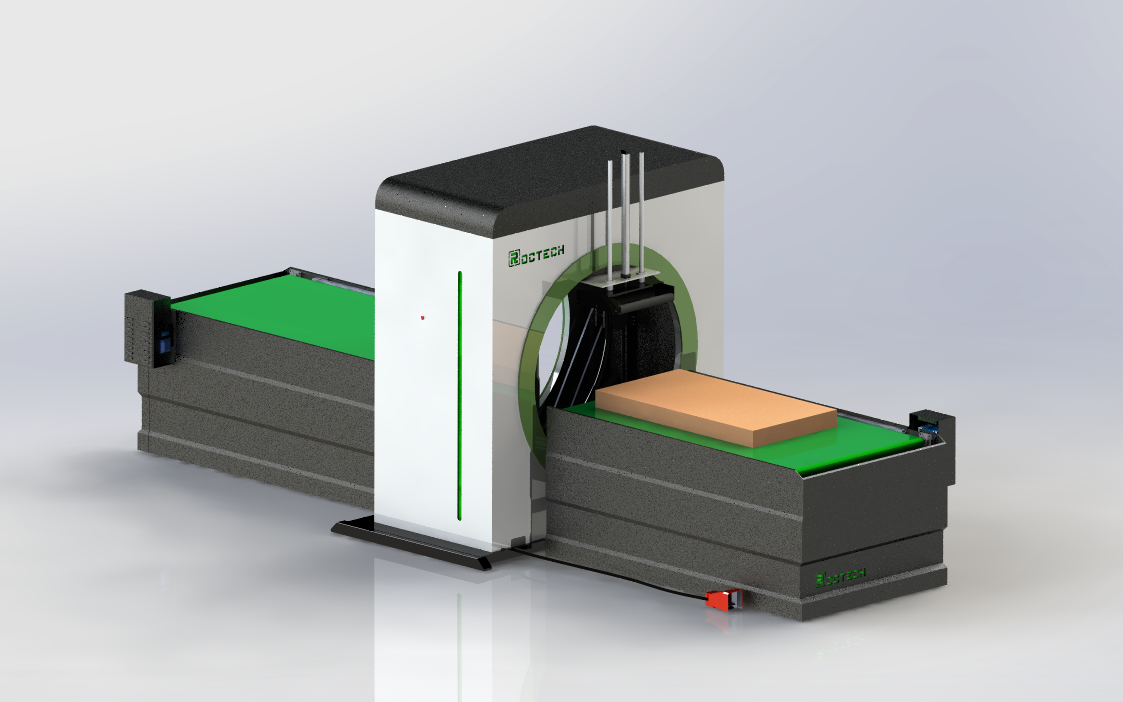

A small laser metal cutting machine is a compact device that utilizes laser technology to cut through various types of metal with high precision. Unlike traditional cutting methods that rely on physical blades or saws, these machines use a focused laser beam to melt, burn, or vaporize the material, resulting in clean, precise cuts. The "small" in the name refers to the machine's size, making it suitable for limited workspace environments without compromising on performance.

Key Features of Small Laser Metal Cutting Machines

1. Compact Design One of the standout features of these machines is their compact size. They are designed to fit into small workshops or even home garages, making them accessible to a broader range of users.

2. High Precision Laser cutting technology offers exceptional precision, allowing for intricate designs and detailed cuts that would be challenging to achieve with traditional methods.

3. Versatility These machines can cut through a variety of metals, including steel, stainless steel, aluminum, brass, and copper. Some models can also handle non-metal materials like wood, plastic, and acrylic.

4. Speed Laser cutting is significantly faster than traditional cutting methods, enabling users to complete projects more efficiently.

5. Ease of Use Modern small laser metal cutting machines come with user-friendly interfaces and software, making them accessible even to those with limited technical expertise.

6. Low Maintenance Compared to traditional cutting machines, laser cutters require minimal maintenance, reducing downtime and operational costs.

Benefits of Using Small Laser Metal Cutting Machines

1. Enhanced Precision and Accuracy The laser beam's ability to focus on a tiny spot allows for incredibly precise cuts, reducing material waste and improving the overall quality of the finished product.

2. Cost-Effective While the initial investment may be higher than traditional cutting tools, the long-term savings in material costs, labor, and maintenance make laser cutters a cost-effective solution.

3. Increased Productivity The speed and efficiency of laser cutting machines enable users to complete projects faster, increasing overall productivity.

4. Flexibility The ability to cut a wide range of materials and create complex designs makes these machines highly versatile, suitable for various industries and applications.

5. Safety Laser cutting is a non-contact process, reducing the risk of accidents and injuries associated with traditional cutting methods.

Applications of Small Laser Metal Cutting Machines

1. Jewelry Making The precision of laser cutting is ideal for creating intricate designs in metal jewelry, such as pendants, rings, and earrings.

2. Automotive Industry Small laser cutters are used to create custom parts, brackets, and components for vehicles, ensuring a perfect fit and high-quality finish.

3. Electronics In the electronics industry, laser cutters are used to create precise components and enclosures for devices, ensuring optimal performance and durability.

4. Signage and Decoration Laser cutting machines are widely used in the signage industry to create detailed and eye-catching metal signs, logos, and decorative elements.

5. Prototyping Engineers and designers use laser cutters to create prototypes of new products, allowing for rapid iteration and testing of ideas.

6. Art and Sculpture Artists and sculptors use laser cutting machines to create intricate metal artworks, combining precision with creativity.

Key Considerations When Choosing a Small Laser Metal Cutting Machine

1. Power and Wattage The power of the laser determines the thickness and type of materials it can cut. Higher wattage machines can handle thicker and harder metals but may be more expensive.

2. Cutting Area The size of the cutting bed is crucial, as it determines the maximum size of the material you can work with. Ensure the machine's cutting area meets your project requirements.

3. Software Compatibility The machine's software should be compatible with your design tools and easy to use. Look for machines that support popular file formats like DXF, DWG, and AI.

4. Cooling System Laser cutting generates heat, so a reliable cooling system is essential to prevent overheating and ensure consistent performance.

5. Safety Features Look for machines with built-in safety features like emergency stop buttons, protective enclosures, and laser safety glasses to protect operators from potential hazards.

6. Brand and Support Choose a reputable brand with a track record of quality and reliability. Consider the availability of customer support, warranties, and spare parts.

Maintenance and Care for Small Laser Metal Cutting Machines

1. Regular Cleaning Keep the machine clean by removing dust, debris, and metal shavings from the cutting bed and laser head. This prevents buildup that can affect performance.

2. Lens and Mirror Maintenance The laser lens and mirrors should be inspected and cleaned regularly to ensure optimal beam quality and cutting precision.

3. Cooling System Check Regularly check the cooling system, including the water or air coolant, to ensure it is functioning correctly and preventing overheating.

4. Software Updates Keep the machine's software up to date to benefit from the latest features, improvements, and bug fixes.

5. Laser Tube Replacement The laser tube is a consumable part that may need replacement after a certain number of hours of use. Monitor its performance and replace it when necessary.

Future Trends in Small Laser Metal Cutting Machines

1. Increased Automation Future machines are likely to incorporate more automation features, such as automatic material handling and loading, reducing the need for manual intervention.

2. Enhanced Software Integration Improved software integration with CAD/CAM systems will allow for more seamless design-to-production workflows, increasing efficiency and reducing errors.

3. Higher Power Lasers As laser technology advances, we can expect to see higher power lasers in small machines, enabling them to cut thicker and harder materials with ease.

4. Smart Features The integration of IoT (Internet of Things) technology will enable remote monitoring, diagnostics, and predictive maintenance, enhancing machine reliability and uptime.

5. Eco-Friendly Solutions Future machines may incorporate more eco-friendly features, such as energy-efficient lasers and reduced material waste, aligning with sustainability goals.

Conclusion

Small laser metal cutting machines have revolutionized the way we approach metal cutting, offering precision, speed, and versatility in a compact package. Whether you're a hobbyist, a small business owner, or part of a large industrial operation, these machines provide a cost-effective and efficient solution for a wide range of applications. By understanding the key features, benefits, and considerations, you can make an informed decision when choosing the right machine for your needs. As technology continues to evolve, we can expect even more advanced and capable small laser metal cutting machines to emerge, further enhancing their value and utility in the metalworking industry.

Regardless of whether you require general advice or specific support, we are happy to help you.