Introduction

In the world of manufacturing and industrial production, precision and efficiency are paramount. When it comes to cutting metal, traditional methods often fall short in terms of accuracy and speed. This is where metal laser cutting technology comes into play, offering a superior alternative that has revolutionized the industry. Among the leading brands in this field is Roclas, renowned for its state-of-the-art fiber laser cutting machines. In this article, we will delve into the benefits of metal laser cutting, explore the features of Roclas machines, and explain why they are the preferred choice for businesses worldwide.

What is Metal Laser Cutting?

Metal laser cutting is a process that uses a high-powered laser beam to cut through various types of metal with exceptional precision. The laser beam is generated by a laser source, typically a fiber laser, and directed onto the metal surface through a series of mirrors and lenses. The intense heat of the laser beam melts or vaporizes the metal, allowing for clean, precise cuts. This method is highly versatile and can be used on a wide range of metals, including steel, stainless steel, aluminum, copper, and brass.

Advantages of Metal Laser Cutting

1. Precision and Accuracy One of the most significant advantages of metal laser cutting is its ability to produce highly accurate cuts. The laser beam can be controlled with extreme precision, allowing for intricate designs and complex shapes that would be difficult or impossible to achieve with traditional cutting methods.

2. Speed and Efficiency Laser cutting is much faster than conventional cutting techniques, significantly reducing production time. This increased speed translates to higher productivity and lower labor costs.

3. Versatility Metal laser cutting machines can handle a wide variety of metals and thicknesses, making them suitable for a broad range of applications. Whether you're working with thin sheets or thick plates, a laser cutter can handle the job with ease.

4. Minimal Material Waste The precision of laser cutting minimizes material waste, as the laser beam can be programmed to follow the exact contours of the design. This not only reduces costs but also contributes to more sustainable manufacturing practices.

5. Clean Cuts Laser cutting produces clean, smooth edges that often require little to no additional finishing. This eliminates the need for secondary processes such as grinding or sanding, further saving time and resources.

Why Choose Roclas Fiber Laser Cutting Machines?

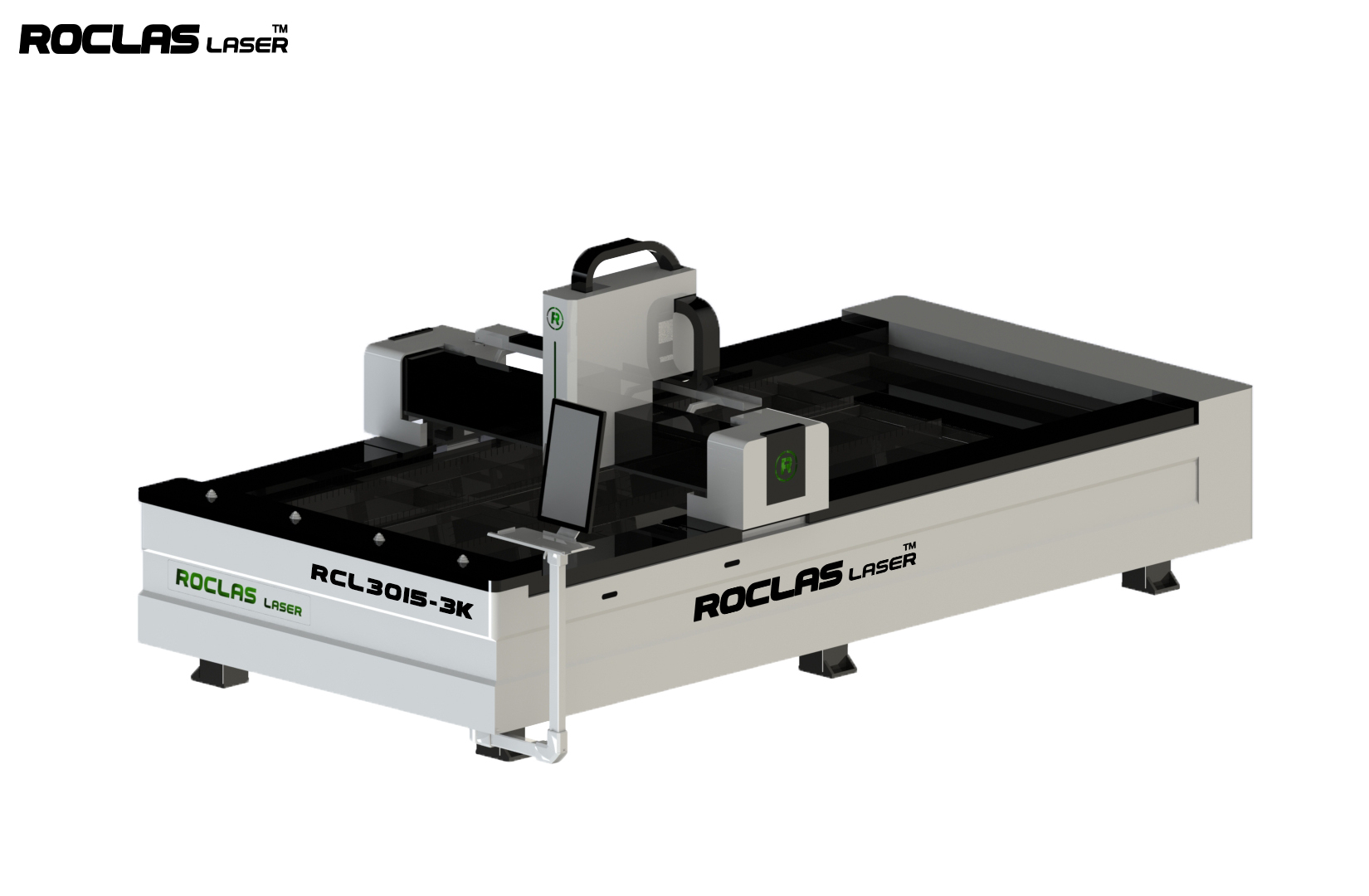

Roclas has established itself as a leader in the laser cutting industry, offering a range of high-performance fiber laser cutting machines designed to meet the needs of modern manufacturing. Here are some reasons why Roclas machines stand out

1. Advanced Fiber Laser Technology Roclas machines are equipped with the latest fiber laser technology, which offers superior cutting speed and precision compared to traditional CO2 lasers. Fiber lasers are also more energy-efficient, reducing operational costs.

2. Robust Construction Roclas machines are built to last, with durable components that ensure long-term reliability and performance. The robust construction minimizes downtime and maintenance, keeping your production running smoothly.

3. User-Friendly Interface Roclas machines feature intuitive, user-friendly interfaces that make them easy to operate, even for those with limited experience. The advanced software allows for precise control over the cutting process, ensuring consistent, high-quality results.

4. Customizable Options Roclas offers a range of customizable options to suit your specific needs. Whether you require a machine with a larger cutting area, higher power output, or additional features, Roclas can tailor a solution to meet your requirements.

5. Comprehensive Support Roclas provides excellent customer support, from initial consultation and installation to ongoing maintenance and technical assistance. Their team of experts is always available to help you get the most out of your machine.

Applications of Roclas Fiber Laser Cutting Machines

Roclas fiber laser cutting machines are used in a wide range of industries, including

- Automotive For cutting precise components and parts.

- Aerospace For manufacturing lightweight, high-strength components.

- Construction For cutting structural elements and architectural features.

- Electronics For producing intricate components and enclosures.

- Art and Design For creating detailed metal artwork and decorative pieces.

Conclusion

Metal laser cutting has transformed the way we work with metal, offering unparalleled precision, speed, and versatility. Roclas fiber laser cutting machines are at the forefront of this technology, providing businesses with the tools they need to stay competitive in today's fast-paced manufacturing environment. With advanced features, robust construction, and comprehensive support, Roclas machines are the ideal choice for anyone looking to enhance their metal cutting capabilities. Invest in a Roclas fiber laser cutting machine and experience the difference for yourself.

Regardless of whether you require general advice or specific support, we are happy to help you.